A 100-year journey

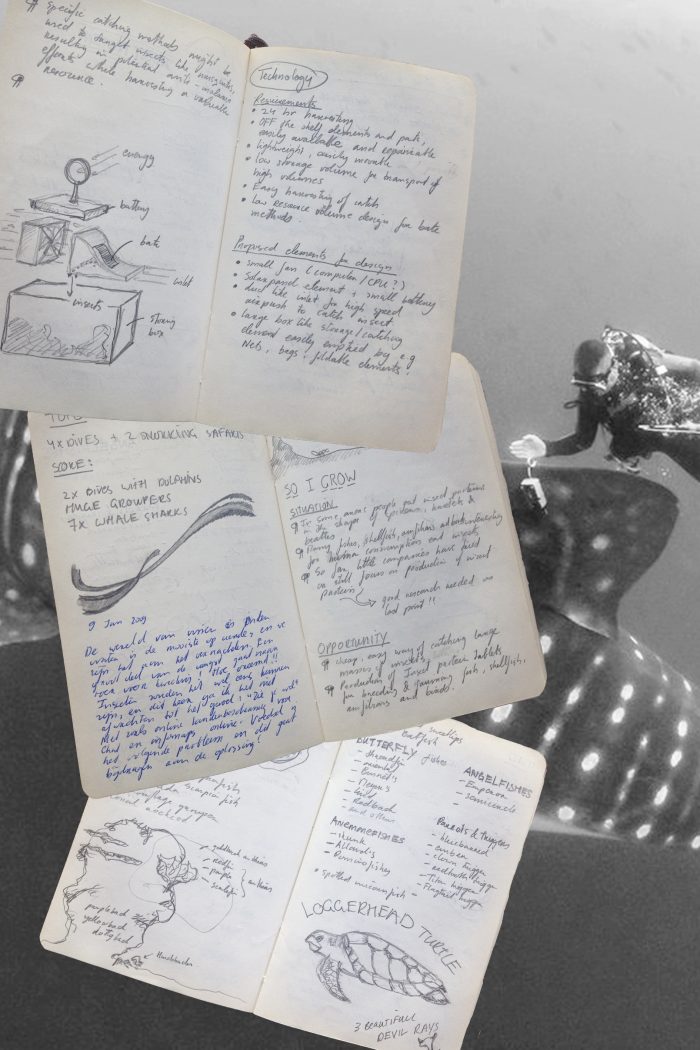

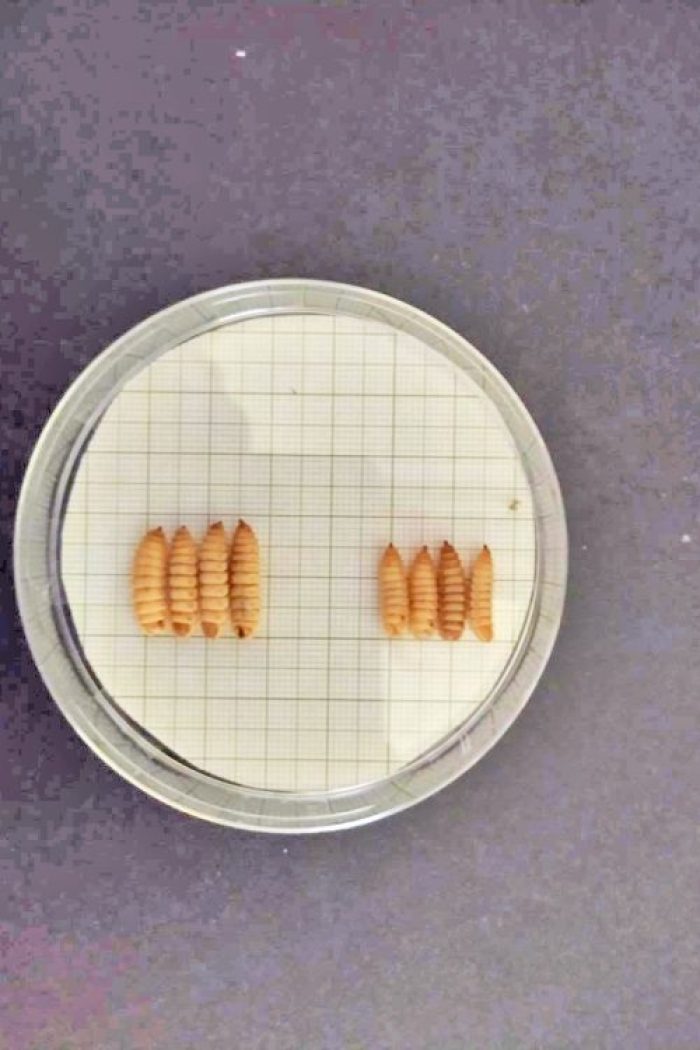

Nine years after its foundation, Protix has far exceeded the phase of startup. Since 2015, the company - which is currently active in twelve countries - has managed to develop unique markets through goal-oriented innovations. For example, its brand of eggs - OERei - is available in Albert Heijn XL supermarkets and online throughout the Netherlands. The eggs are laid by chickens that were fed Protix larvae, and offer a natural, healthy and sustainable alternative to the current selection of eggs. "Tasty and logical," is how OERei summarizes it. Since the acquisition of Fair Insects in September 2017, Protix has been involved in producing mealworms, crickets and grasshoppers for direct human consumption.

Meanwhile, Protix has grown to 55 employees, which is expected to go up to over a hundred by the beginning of 2019. Their management team has been expanded with Bas Jürgens (Chief Operating Officer), Stijn Harms (Director Capital Projects), Tiemen Dalhuisen (Chief Financial Officer), Eric Schmitt (Chief Research & Development), and Malgorzata Fijalkowska (Manager of Fair Insects). The construction of the first major production facility in Bergen op Zoom has begun. Protix is planning to celebrate its 10th birthday in the new facility. Where will the company be in a couple of years? "We will be the undisputed market leader in the worldwide insect industry and will be showing profitable growth based on mass production, so that we can have a significant impact on the food chain and the balance between mankind and nature."

"This is reflected in our logo: the yin and yang shapes represent the insects that balance our planet, and with a bit of effort you can see the infinity symbol that represents our food system. Regardless of the number of people who are living on this planet, we will have to feed them all. It's crucial that everyone has access to healthy and affordable food. This offers endless possibilities and challenges that we can all solve through innovation. As Protix, we stand for long-term impact. This is only the beginning of our 100-year journey.